Production Part Approval Process (PPAP) Support

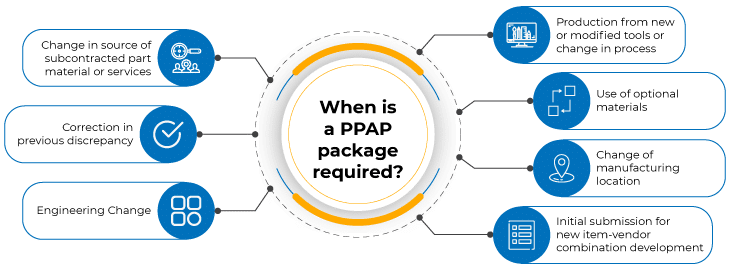

Automotive suppliers have to go through the Production Part Approval Process (PPAP Support), which is the industry standard governed by the Automotive Industry Action Group (AIAG). An efficient and well-managed PPAP ensures that engineering design and product specification requirements are met, thereby improving the reliability of components and assemblies provided by third-party vendors.How to Perform Production Part Approval Process (PPAP)

Enventure provides PPAP support and First Article Inspection (FAI) services for Automotive as well as non-Automotive companies, to confirm that the part or assembly is being supplied is acceptable. The PPAP process also confirms that the processes used to manufacture parts can consistently reproduce the parts at defined quality levels and in compliance with specifications. As completing PPAP submission is time-consuming, it often becomes a significant workload for Supplier Quality teams – which is why clients leverage the skills and expertise of the Enventure team. Enventure’s clients have realized the benefits of outsourcing a supplier quality function like PPAP, as it has proven to be a process that is both easy to outsource, as well as very cost-effective. Moreover, an efficient PPAP process can save manufacturers significant time and money, as well as avoid failures and recalls, which can be fatal to the business.