Equipment and Asset BOMs

We create spare BOMs (Bills of Materials) for assets and equipment, to enable easy identification of the right spares, ensure critical stock availability, create Spare Parts Interchangeability Records (SPIR) and optimize procurement. Multiple types of BOMs are created and maintained, such as – Equipment BOMs, Functional location BOMs and Material BOMs. In an ideal world, all asset-intensive industries would have an exact correlation of MRO spares to equipment, to minimize downtime and make sure that any faults or breakdowns are dealt with quickly and efficiently, apart from creating a reliable maintenance plan. But in the real world, that is far from the truth. Without a well-structured spares strategy, businesses are left with one of two options: either they stock everything they may need, or they make reactive purchasing decisions based on the needs of the moment. Both come with significant costs and inefficiencies, which no organization can afford in today’s world. Our multi-level equipment BOM services enable you to create hierarchical equipment/asset BOMs, with information about spare criticality, as well as specifications and details relevant to maintenance, engineering, and supply chain.An effective Equipment BOM ensures:

- Clear identification for spares for assets and equipment

- Efficient equipment maintenance planning & scheduling

- Optimize MRO inventory and reorder levels

- Expedited procurement, with standardized material requisitions

- Easy allocation of available MRO spare parts

- Optimized MRO material lifecycle management by eliminating obsolete parts

- Real-time visibility to part substitution and alternate options

- Superior data integration between ERP and EAM

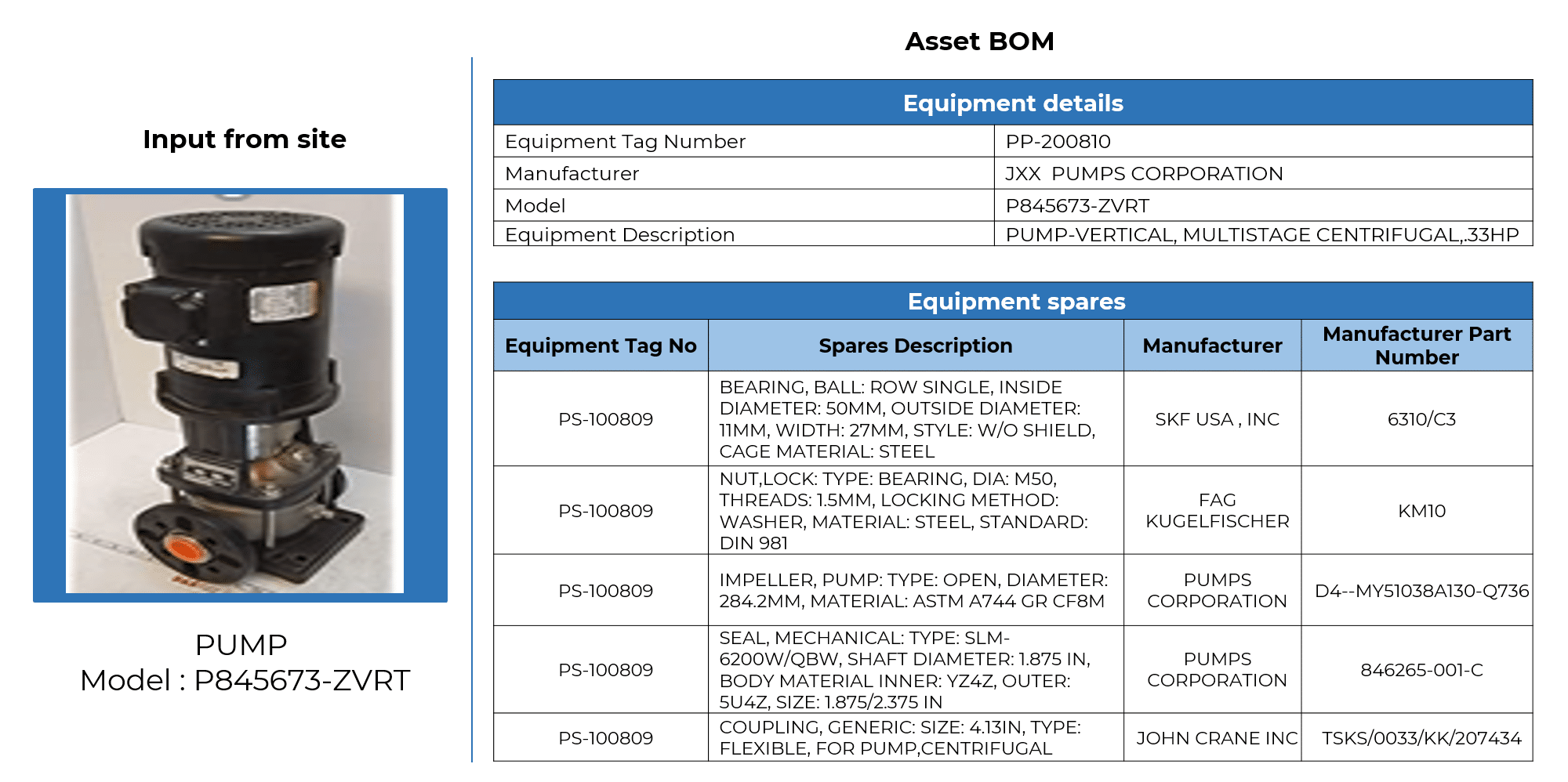

Here is a sample Asset BOM

BOM Cost Reduction

BOM Cost Reduction boosts client savings, and enhances sales & margins.

Read More about BOM Cost Reduction

Asset BOM and Plant Reliability

The Asset BOM has a direct impact on Plant Reliability

Read More about Asset BOMs in Reliability

Equipment and Asset BOM Benefits

What are the Top Benefits of Equipment / Asset BOM

Read More about BOM Benefits