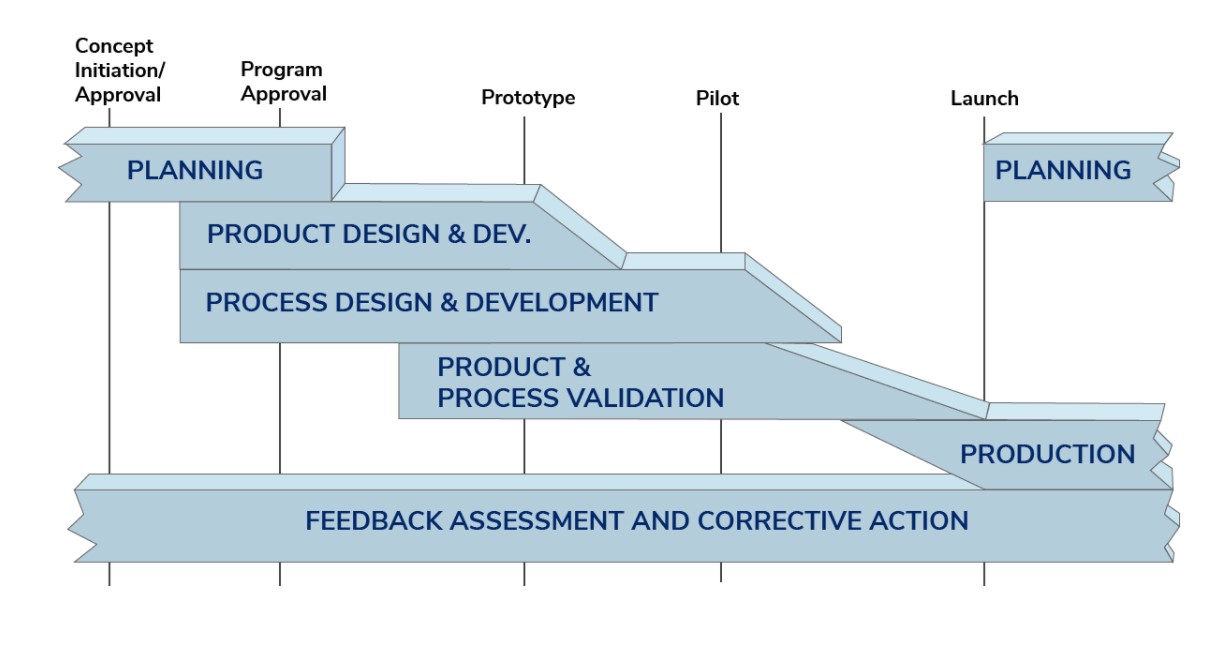

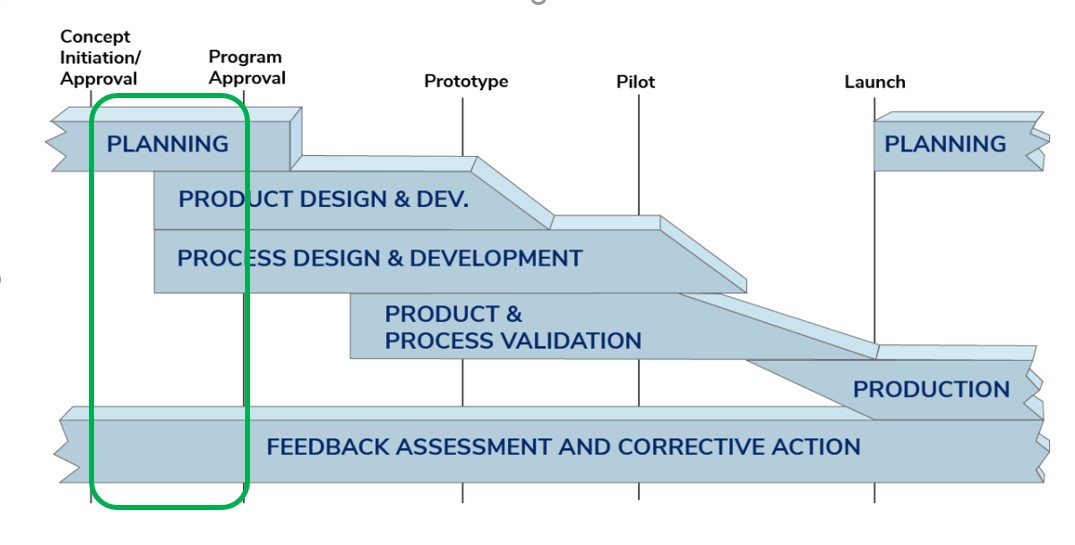

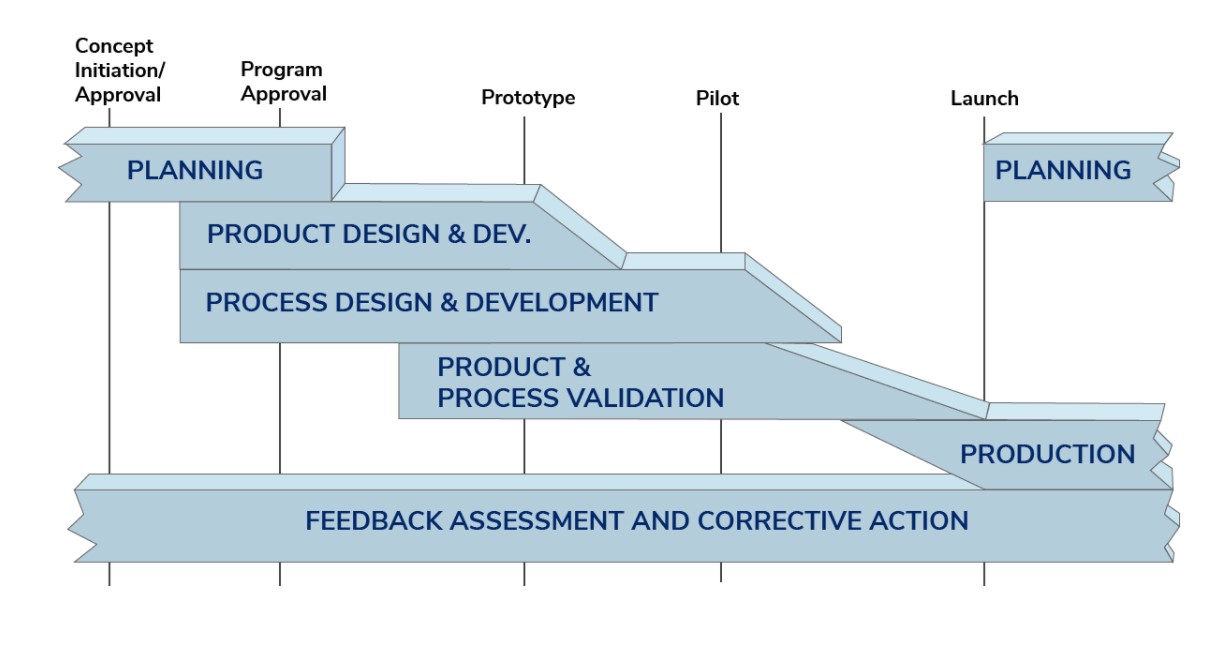

Stages in a Robust APQP Process

September 9, 2021

Tags: APQP, APQP documentation, APQP process, PPAP, PPAP Approval Process, PPAP documentation

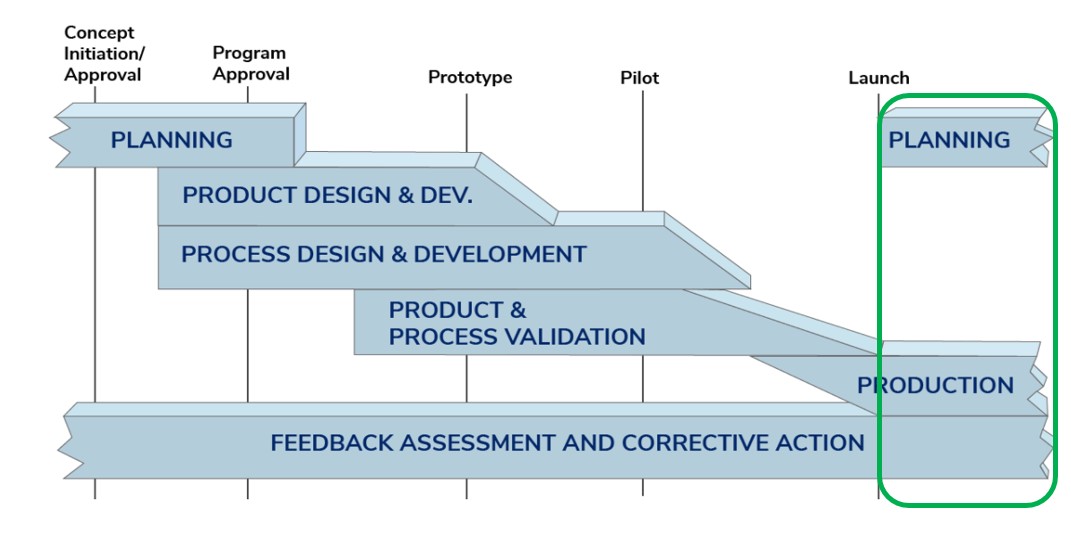

The APQP process consists of five stages:

The flow of stages involved in the APQP are such that the output of one stage acts as input of subsequent stage.

- Planning

- Product Design and Development

- Process Design and Development

- Product and Process Validation

- Feedback and Continuous Improvement

Stage 1: Planning

In this stage supplier understanding the customer requirements and expectations.

Input |

Output |

Voice of Customer

|

Design goals |

| Business plan/marketing strategy | Reliability and quality goals |

| Product/process benchmark data | Preliminary Bills of Materials |

| Product reliability studies | Preliminary listing of special products and process characteristics |

| Customer inputs | Product assurance plan |

| Management support |

Stage 2: Product Design and Development

Stage 2 verifies design feasibility and compliance.

Inputs (from Stage 1 outputs) |

Output |

| Design goals | Design failure mode and effects analysis (DFMEA) |

| Reliability and quality goals | Design for manufacturability and assembly |

| Preliminary bill of materials | Design verification |

| Preliminary process flow chart | Design reviews |

| Preliminary listing of special products and process characteristics | Design reviews |

| Product assurance plan | Engineering drawings (including math drawing) |

| Management support | Material specifications |

| Drawing and specification changes |

Stage 3: Process Design and Development

Stage 3 verifies the manufacturing capability and measurement methods.

Inputs (from Phase 2 outputs) |

Outputs |

| Design failure mode and effects analysis (DFMEA) | Packaging standards and specifications |

| Design for manufacturability and assembly | Product/process quality system review |

| Design verification | Process flow chart |

| Design reviews | Floor plan layout |

| Prototype build – control plan | Characteristics matrix |

| Engineering drawings (including math drawing) | Process failure mode and effects analysis (PFMEA) |

| Material specifications | Process instructions |

| Drawing and specification changes | Measurement systems analysis plan |

| Preliminary process capability study plan | |

| Management support (including operator staffing and training plan) |

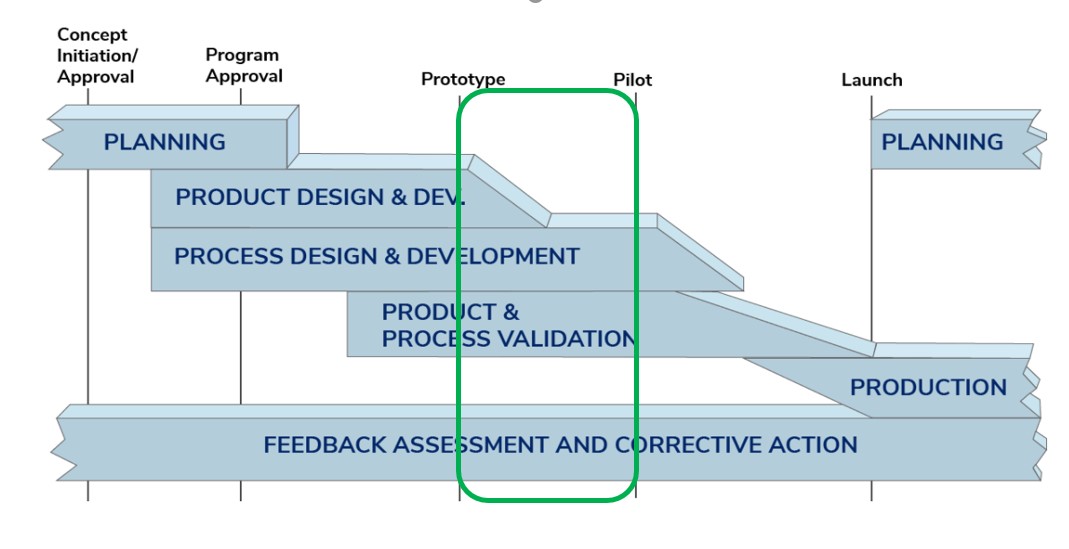

Stage 4: Product and Process Validation

Stage 4 validates the complete manufacturing process and final product.

Inputs (from Phase 3 outputs) |

Outputs |

| Packaging standards and specifications | Significant production run |

| Product/process quality system review | Measurement systems evaluation |

| Process flow chart | Preliminary process capability study |

| Floor plan layout | Production part approval |

| Characteristics matrix | Production validation testing |

| Process failure mode and effects analysis (PFMEA) | Packaging evaluation |

| Process instructions | Product control plan |

| Measurement systems analysis plan | Quality planning sign-off and management support |

| Preliminary process capability study plan | |

| Management support (including operator staffing and training plan) |

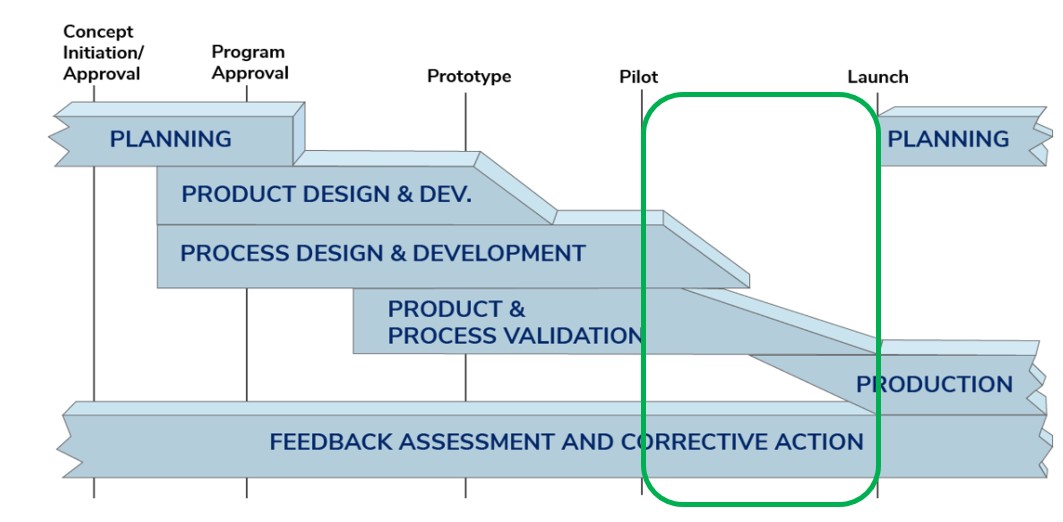

Stage 5: Feedback and Continuous Improvement

Stage 5 closes the feedback loop.

Inputs (from Phase 4 outputs) |

Outputs |

| Significant production run | Reduced variation |

| Measurement systems evaluation | Improved customer satisfaction |

| Preliminary process capability study | Improved delivery and service |

| Production part approval | Effective use of lessons learned |

| Production validation testing | |

| Packaging evaluation | |

| Control plan | |

| Part submission warrant | |

| Quality planning sign-off and management support |