MRO Data Cleansing and Enrichment

Enventure provides MRO Data Cleansing and Enrichment services to clients across various industries, such as Manufacturing, Mining, Oil & Gas, Food & Beverage, Energy, Pharma, and Chemical. For any asset-intensive company, the MRO supply chain is a critical element in improving plant uptime and enhancing plant reliability. Ensuring the right part is available at the right time is a non-negotiable need; the key is to do this while avoiding costs of disorganized purchasing or overstock. MRO Data Cleansing and Enrichment lead to implementing a unified and accurate database of MRO parts (Material Master) for your organization. The process involves consolidating data from different systems (EAM, ERP, CMMS systems) at the client’s end, reviewing what data is relevant to the business today, and then undertaking the cleansing and enrichment activity to create a golden database. This database would be deduplicated and classified accurately, with standardized descriptions that provide the required level of detail to support internal decisions. The database also supports spend analytics and drives business intelligence, which is very valuable for optimizing the MRO spend, while giving weightage to risk and criticality-based maintenance programs. Over the years, Enventure has processed millions of MRO materials, covering over 10000 commodities across multiple industries. Our reference database enables us to be efficient and quick in turning around projects.Some of our other key differentiators include:

- PartLinq, our proprietary AI-based platform for MRO data optimization

- Enventure standard taxonomy, which can be customized for clients as needed

- Millions of parts are available in our reference database

- Engineering domain experts across disciplines– mechanical, electrical, instrumentation, etc

- Tenured engineering leadership with process knowledge across industries

Our MRO Data Cleansing and Standardization Services include:

- Data Audit, analysis, and report

- New Material Material Cataloging creation

- Legacy MRO Data cleansing, classification, enrichment, and standardization

- Taxonomy implementation and training

- Crib crawling, warehouse walk downs

- Data upload to SAP, Maximo, Oracle (Or any major EAM / CMMS / ERP systems)

- MRO Data Governance

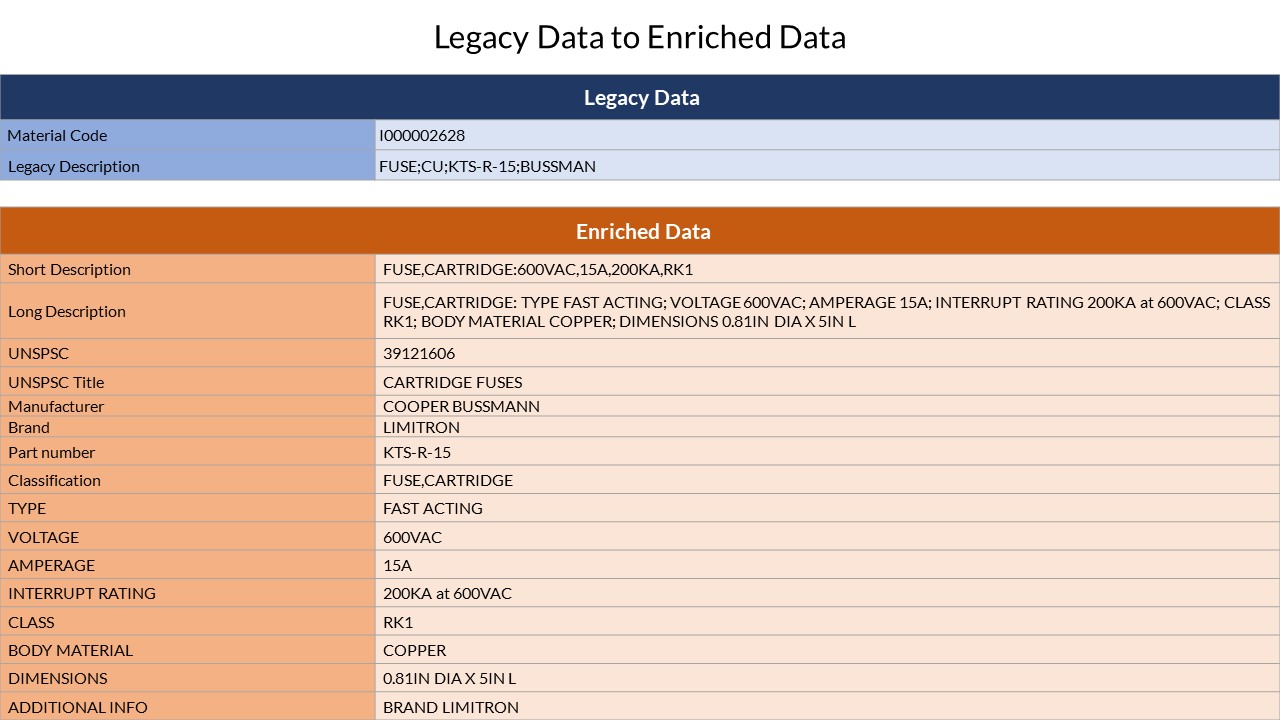

Here is a Sample of Data Enrichment:

Vendor Master Services

Apart from MRO materials, we also assist clients in updating and maintaining the vendor master, since efficient vendor management is paramount to control costs, manage inventory and optimize the supply chain.Our Vendor Master Services include:

- Analyze and identify gaps in vendor master data

- Collect and update missing /inaccurate vendor profile info

- Vendor classification as per NAICS or SIC

- Deduplication and hierarchical organization

- Vendor Onboarding

- Vendor Master Maintenance

Product Information Management

Enventure offers a complete Product Information Management service to implement a successful e-commerce strategy, to enhance the consumer experience, boost sales, and improve analytics for omnichannel sales. Our services are holistic in nature, covering everything from information sourcing (via web and direct engagement), validation, normalization, enrichment, curation, and cross-referencing. We also engage with clients in creating their PIM Blueprint, covering the data model, taxonomy, attribute schema, and ongoing data governance system.

MRO Data Audit

Analyze the master data quality in your ERP/EAM/CMMS systems

Read More about MRO Data Audit

MRO Data Taxonomy

Unified MRO Taxonomy help your analyze spend & improve supplier terms

Read More about MRO Data Taxonomy

MRO Data Catalog

Generate MRO catalog as per established ISO 8001 standards & Optimize BOMs.

Read More about MRO Data Catalog

Vendor Master

create, update and optimize supplier base, across systems, locations & geographies.

Read More about Vendor Master