More on PCB Design and Lead-Free Finishes

Component engineering firms outside the EU are using ROHS WEEE legislation to decide which components to keep for export – and which to make obsolete. Despite being free of RoHS and WEEE legislation themselves, their customers in Europe and the UK are not – and are liable to prosecution if they use components containing lead and other substances banned by the EU.

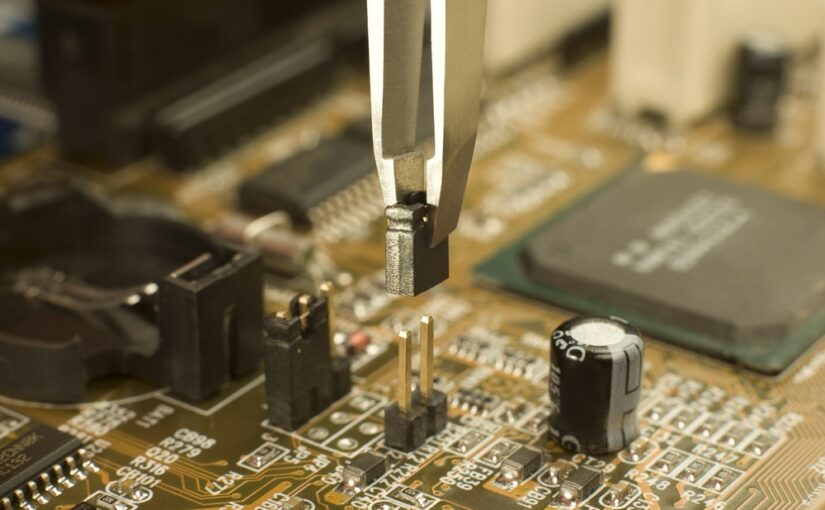

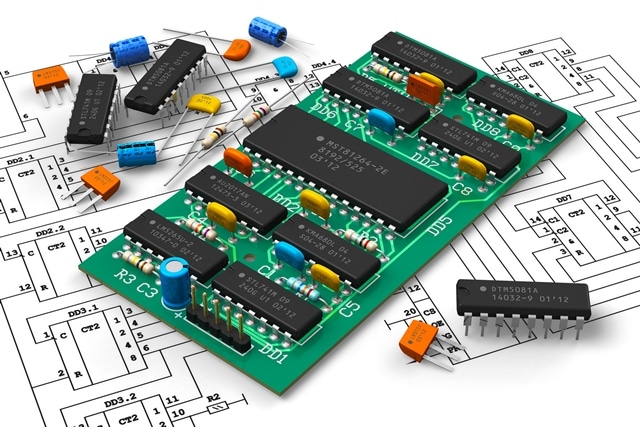

This means the list of obsolete semiconductors is growing, fuelled by a need to make FPGA design and printed circuit boards predominantly lead-free. Tin-lead (SnPb) finishes have given way to lead-free ones, causing major headaches in BOM management. There are certain sectors of industry exempt from the ROHS directive, under categories 8 and 9 of the ruling; for example medical instrument, environmental monitoring and military hardware design. However, few basic components these days are custom-produced (except, perhaps, at the conceptual stage of design.) Even military hardware relies on “off-the-peg” components nowadays, which are becoming obsolete. This is compounded by the fact the exemptions have a finite time span – by 2012, many lead-free alternatives will need to be found to SnPb components in use today.

Military hardware design companies in the EU have embraced the RoHS directive as best they can, using component cross reference tools and BOM management solutions to ensure an unbroken supply line. It’s essential that military aircraft, for example, are not grounded due to poor obsolescence management (or worse, made unsafe by not replacing faulty or old components due to non-availability.)

It doesn’t hurt to adapt a military approach, even if you’re not involved in military design. We at Enventure Technologies have a range of high value engineering services that include BOM and part obsolescence management solutions.